One of the core services we offer at Flowcav is CFD modelling.

What is CFD?

Computational Fluid Dynamics (CFD) is the use of computer simulation for the prediction of fluid-flow phenomena.

How Does CFD Modelling Work?

Fluid (gas and liquid) flows are governed by partial differential equations which represent conservation laws for the mass, momentum, and energy. By using algebraic equations and special numerical techniques, the density, viscosity, pressure, temperature and velocity can be ascertained at any point in space and time for a flow regime.

What can be Analysed / Application Areas?

Within the automotive sector, CFD is used to analyse the air flow around vehicles resulting in improved aerodynamic drag and favourable lift/downforce. It is also used to study the unsteady flow via internal combustion engines and to study the mixing of liquid fuel with the induced air.

Other fields where CFD is used are in aircraft design, powerplant design, chemical plants, ventilation in large buildings, blood flow via the human body etc

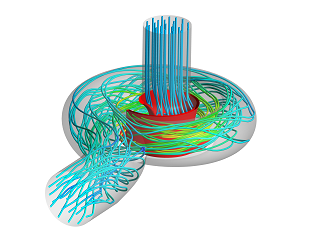

Shown below is the CFD output for the unsteady gas exchange process in a large bore two-stroke engine - carried out by Flowcav Ltd.

Why choose Flowcav for CFD modelling?

When undertaking CFD analysis, combining engineering science expertise with hands on real-world industrial knowledge is key to success. At Flowcav, we are confident that our engineers are the best in the business - in large part because of their ability to relate fluid analysis to hardware.

Our unique blend of skills and process know-how turns attribute-based engineering into a true competitive advantage for you. Here are several more good reasons to choose Flowcav for CFD analysis:

- Our track record in CFD analysis. Our experience spans from concept and initial design optimization, detailed modelling and predictive studies to prototype refinement.

- Flowcav engineers are true partners who work with customers to solve their most critical design and development challenges. This knowledge transfer can make the difference between a successful product launch and costly recalls and repairs or even product failures.

- Access to the Best Analysis Tools: At Flowcav, we have tried and tested all the major CFD analysis tools.

- Avoid layers of middle management: When dealing with Flowcav, customers have direct access to our engineer and are aware of exactly who is working on their problem, and how it is progressing.

- Doing buisness with us is easy: At Flowcav, as a small organisation, we believe in only taking on work which we can handle. We'll tell you straight whether we can assist you, what the likely cost and scope of work will be upfront. We respect that projects we work on can be commercially sensitive. To avoid any conflict of interest and provide reassurance for clients, we explicitly choose not to avoid working with competitors within the same industry.

Thinking of Pushing the Boundaries?

At Flowcav, as well as tackling the more routine analysis, we enjoy taking on the more demanding challenges and problems. This allows us to benchmark our performance against the very best, and ensure that we remain at the forefront of analysis

Two specific areas where we are pushing boundaries are as follows:

- CFD Analysis of Subsystems: We are now using full CFD analysis to model much more of systems than would previously have been possible

- Coupling of CFD with one-dimensional Analysis: Flowcav have access to customised software which allows us to couple one-dimensional analysis with CFD thereby giving a total hydraulic solution, with the optimum combination of speed and localised detail where required

By combining and customising library components, Flowcav can quickly create an easy to understand working sketch of the system model. Often, Flowcav engineers start from greatly simplified representations in the early development stages and gradually add more detail aas design information becomes available.

Contact Flowcav now and we will happy to answer any further questions you may have.